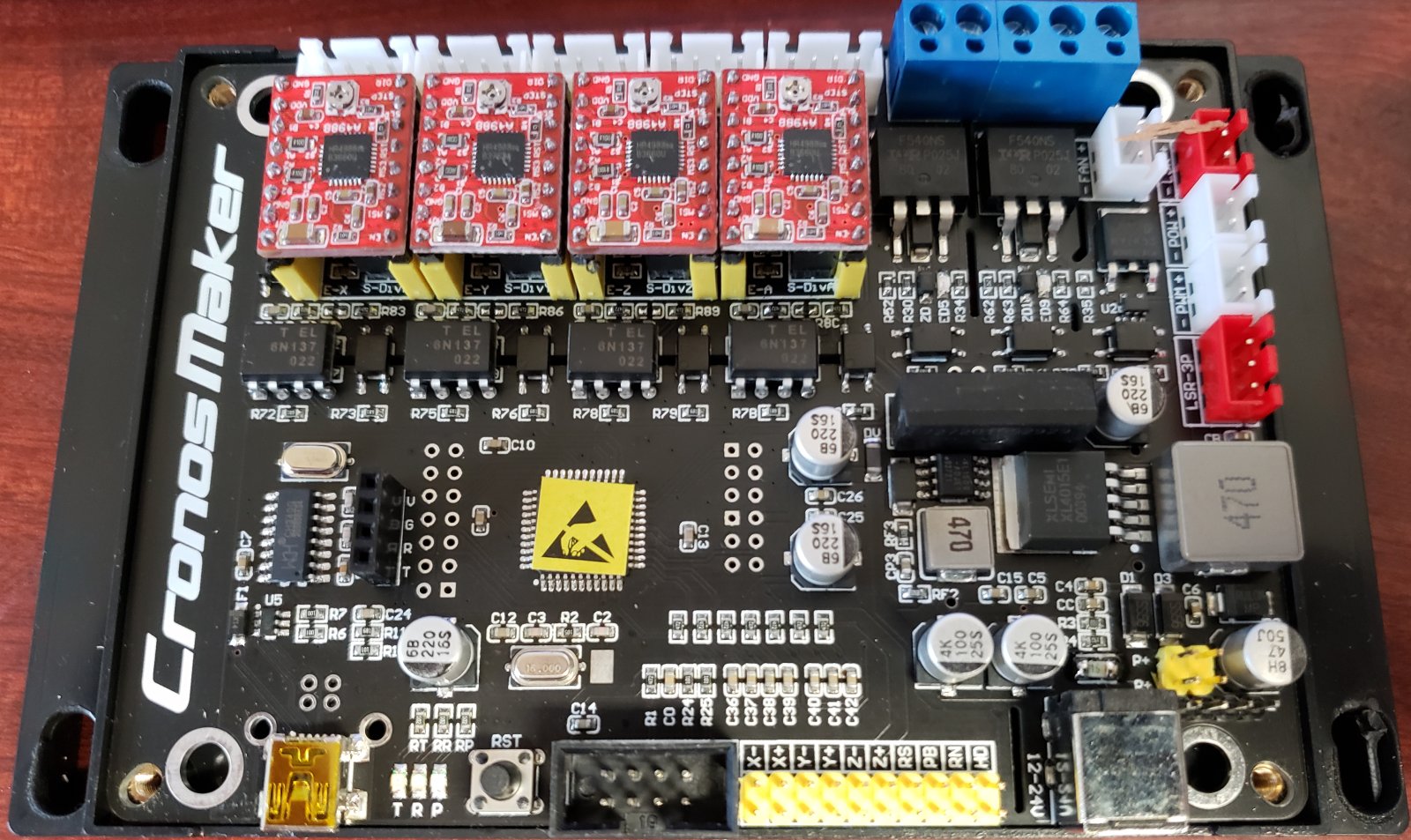

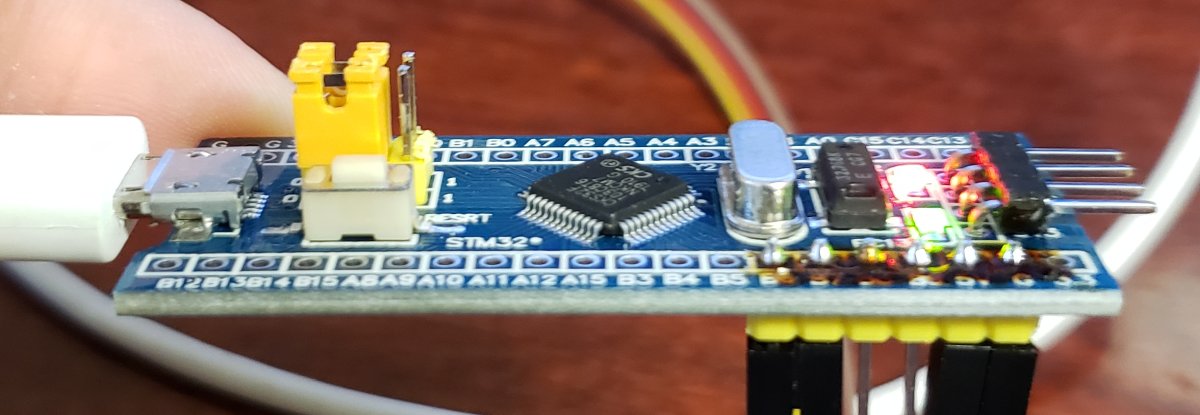

STM32 is an awesome alternative to Arduino board. Unlike 328P, it has native (fast) USB support. It is cheaper than 32U4. And it faster, 32 bit and has 10x more RAM!

Also, unlike Atmel, counterfeits wannabes are clearly identifiable (look at the microcontroller on your board. If it is CH32 – throw it into a trash can. STM32 and CKS32 are good)

It is easy to make it work – just follow the instructions:

STM32 Arduino Instructions

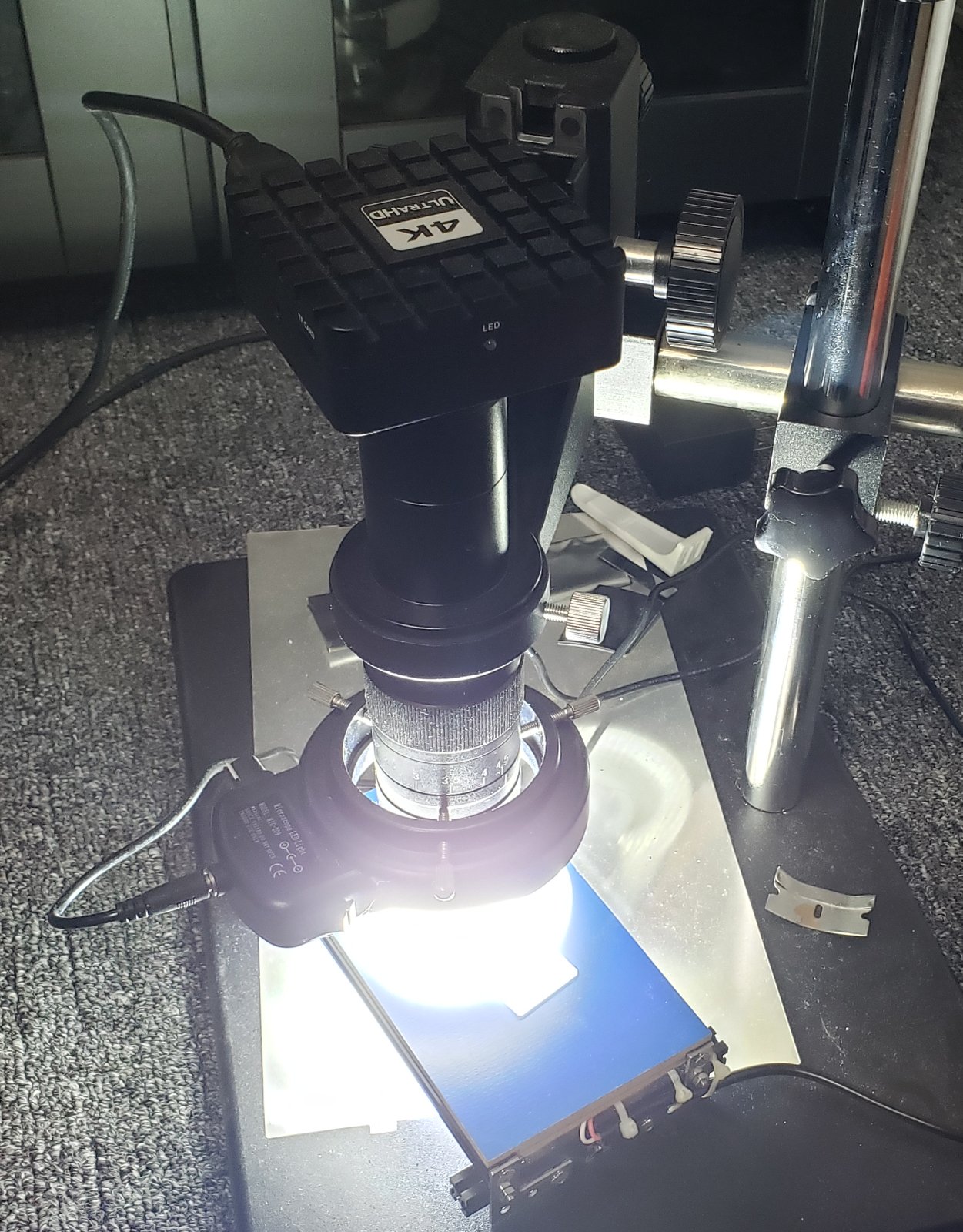

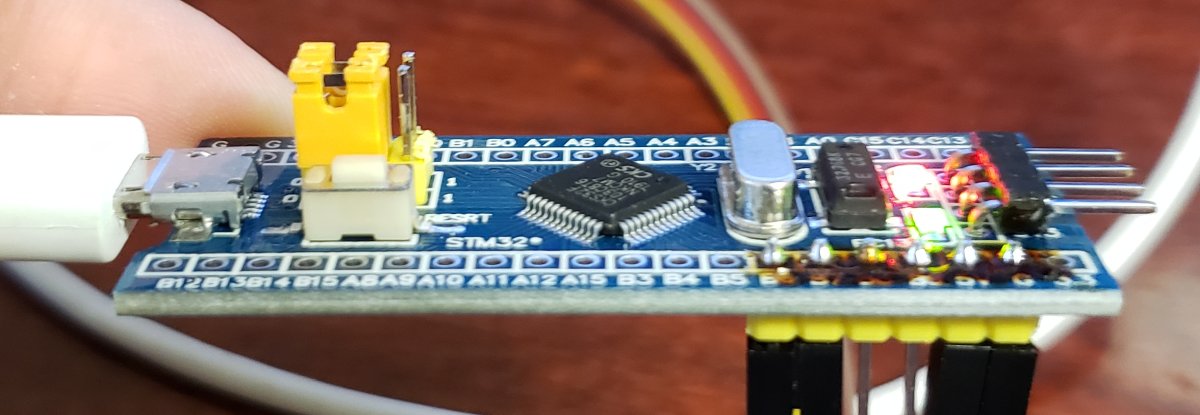

(you can also use ST-Link V2 and connect to the board via 4 wires. I have found this approach very reliable. You can both flash firmware and upload sketches from Arduino IDE. I set both boot header switches to “1″ when I do it. But programming via USB is more convenient, right?)

Ok, so you follow the instructions from Windows 10 PC and try to program your board via the USB and it cannot find the DFU.

Continue reading →