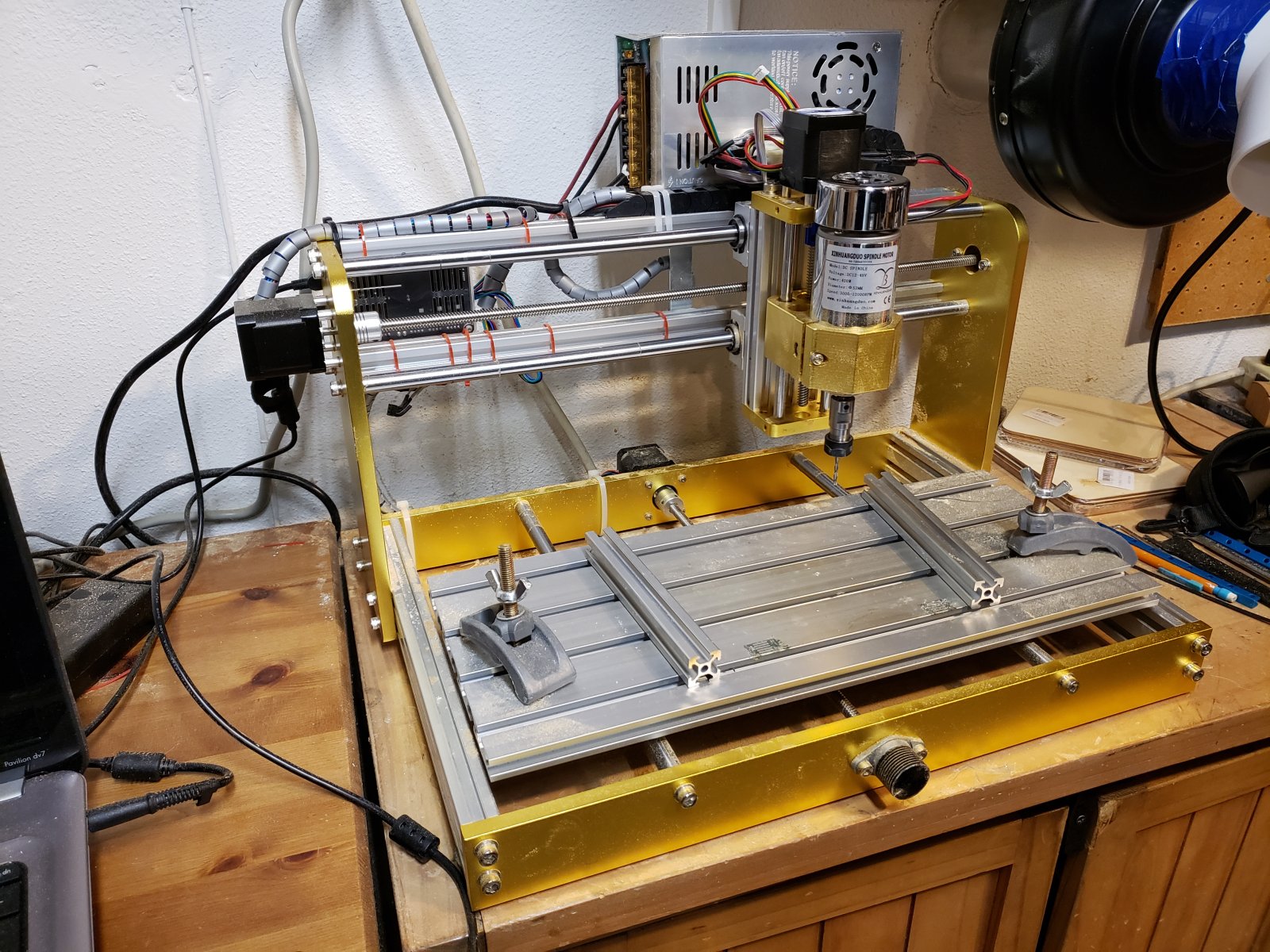

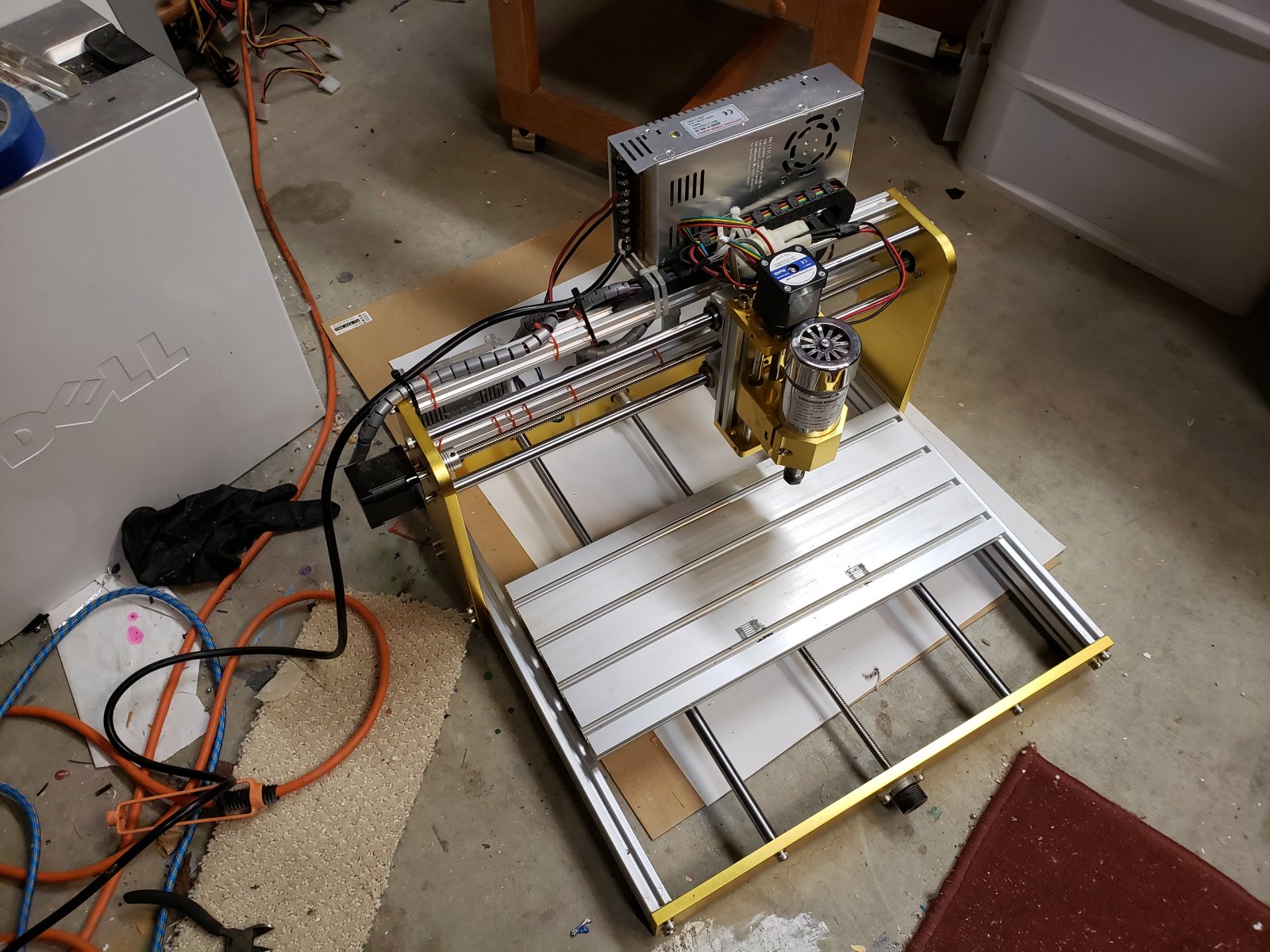

Here is my old good 4018:

The problem is – 180 mm in Y is sometimes limiting my project ideas. But how to upgrade it?

I would need a longer 8mm leadscrew, two longer 12mm rods and two longer 2040s.

I can buy them on Aliexpress and cut to size. But 12mm rods shall also be drilled and threaded from the ends. And they are from a hardened steel. I do not have a lathe.

But look at 4018 again. Did you notice that X axis has longer rods and leadscrew?

So I wrote to the manufacturer of 4018 (Doesbot) and asked for the rods and leadscrew and if possible 2040. They said – no 2040s, but we can send you the rods and the leadscrew – surprisingly cheap!

Here they are, arrived.

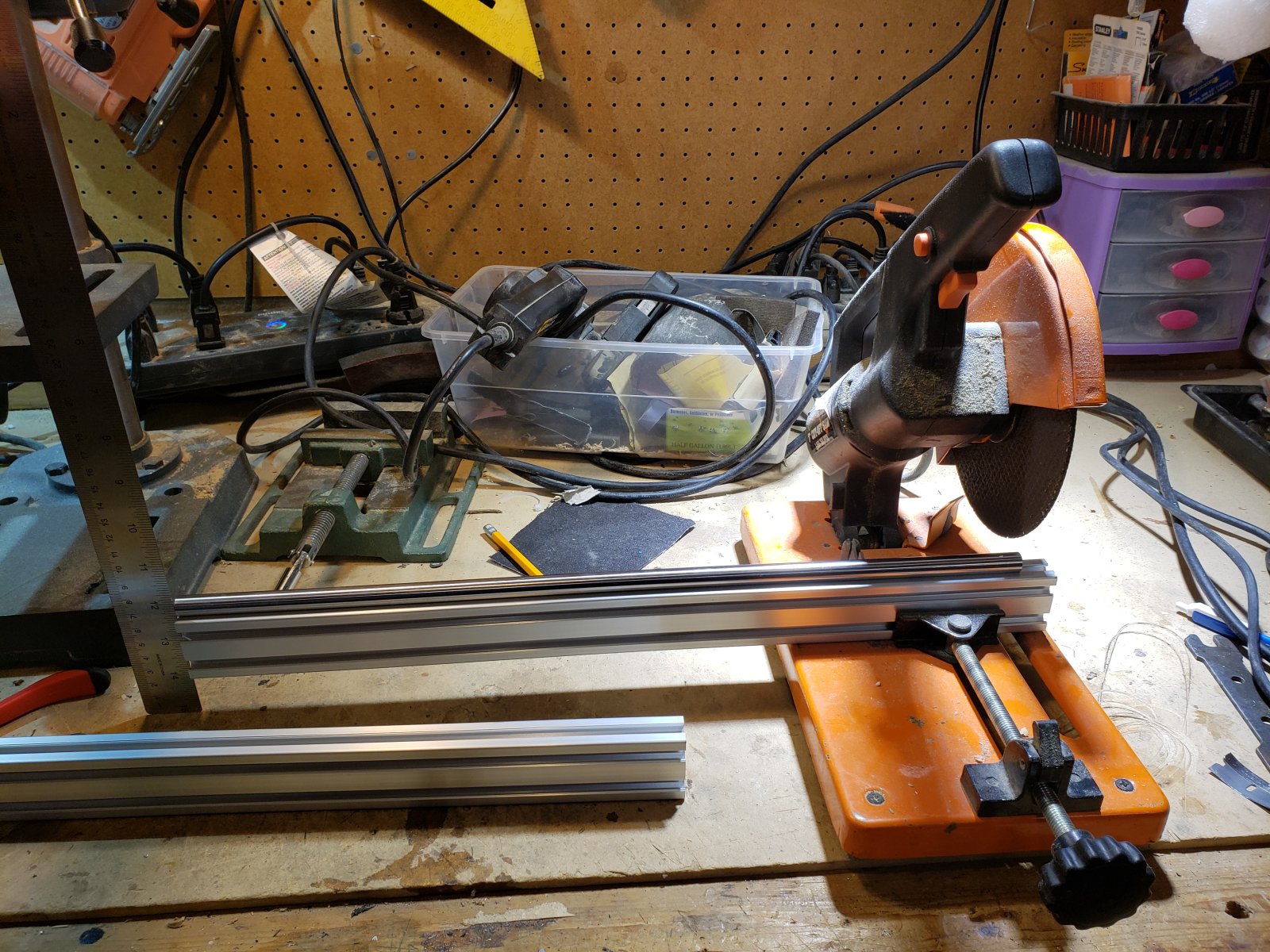

I also had 2040, but they needed to be cut to the size

I cut them with my metal cutter.

It took forever and result was inaccurate and not very perpendicular. I had to fit them and they were too short. I ended up creating shims. But with shims everything fits perfectly.

The piece of 2040 on the picture is just for explanation of of the shims shape.

Then I had to tap 2040. It took me a while and I broke 2 taps and wasted 2 2040 before I figured it out. Here is the story: Tapping Aluminum

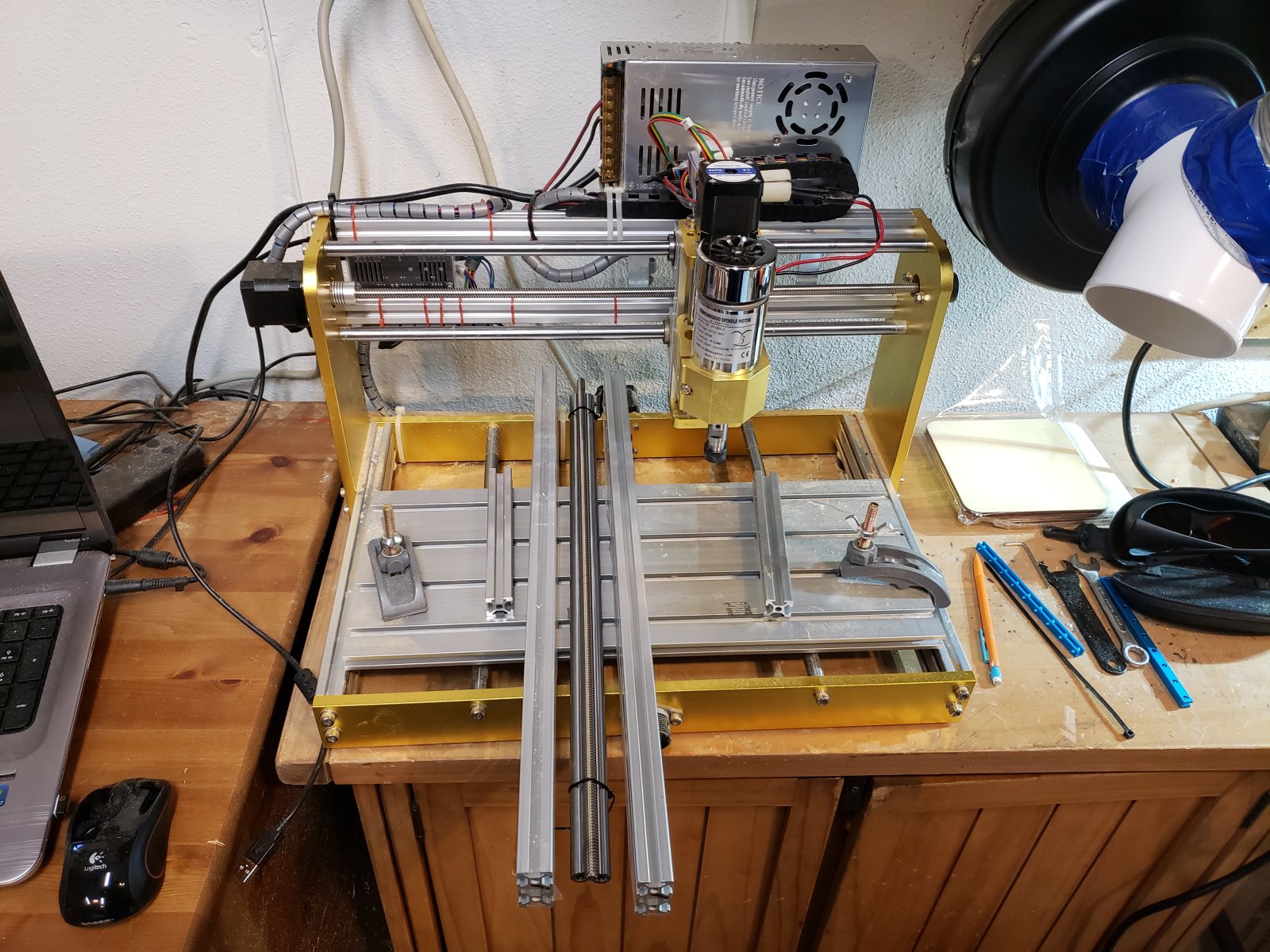

Then I took 4018 apart and replaced Y-axis rods, the leadscrew and 2040s.

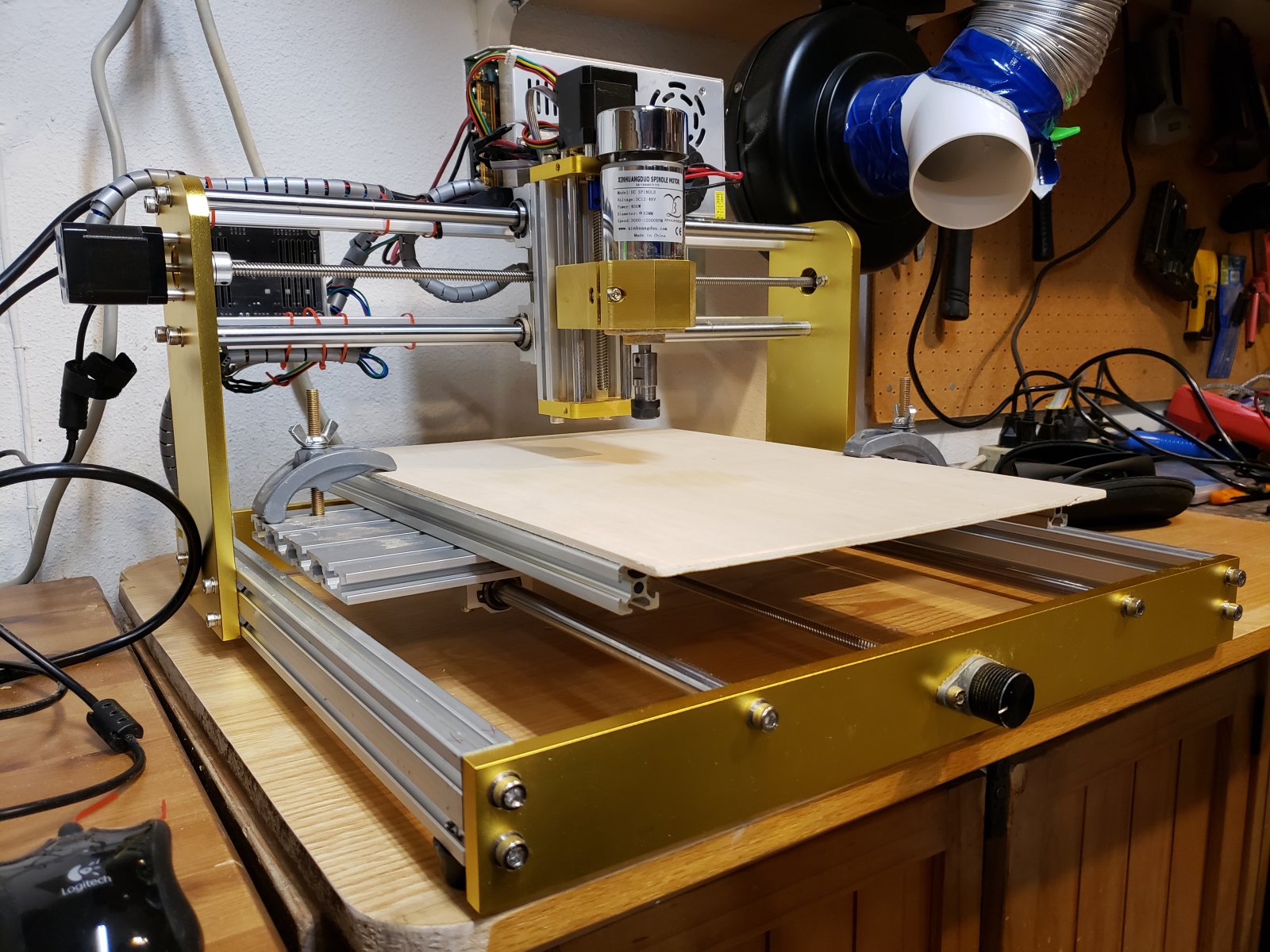

I had to move the X axis 80mm backward so the bit is still centers. 18cm+8cm+8cm is 34cm, so now I have 4034 CNC.

Kind of. Because the bed is still 40 x 18, not 40 x 34 cm.

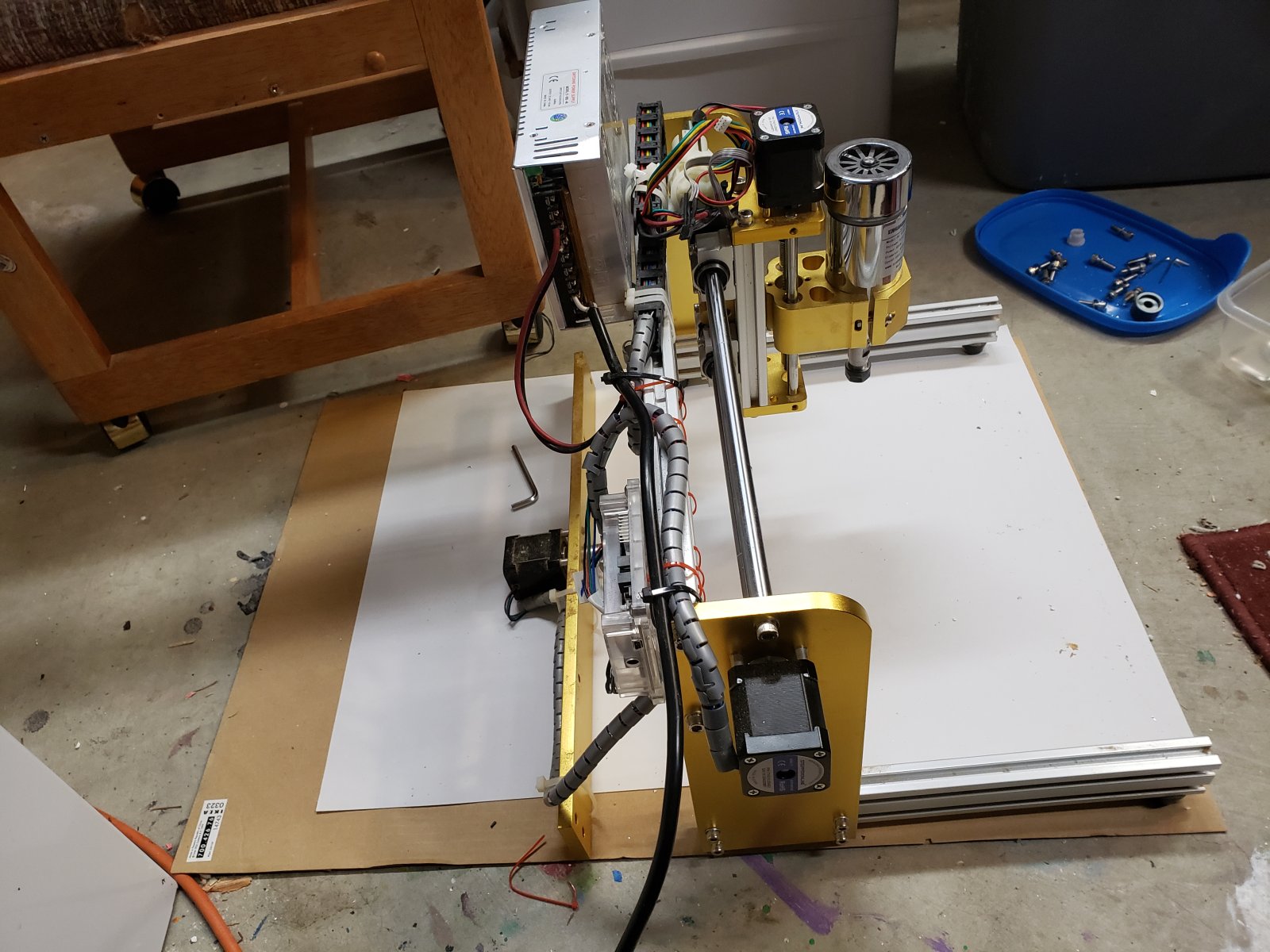

I knew it and I am Ok with that. My main use-case is cutting stuff out. To preserve the base, I lift it on 2020. I can just use longer 2020s and it will stay in place as long as I clamp it well. Like this:

Oh, and the “table” was to short for the upgraded CNC, so I had to make a new table top.