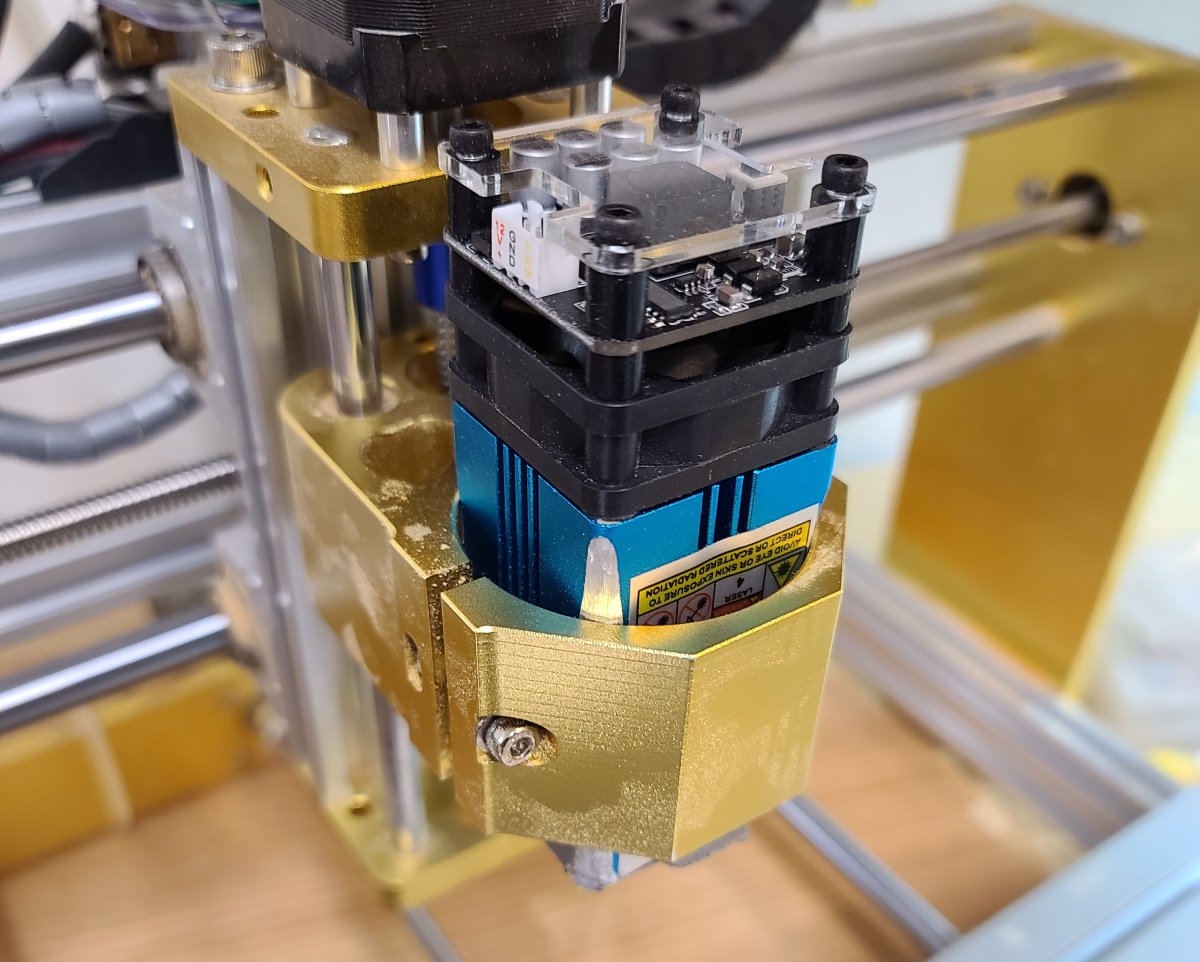

This is not Neje and not 80w. This is shady “40w” laser from Aliexpress.

Guess why did I polish off the corners like that?

to fit it into 52mm spindle mount

Unfortunately, this laser was dead on arrival. It produced a spot, got warm, but did not burn. I disconnected LED from the controller and applied current from a current source straight to the laser. I went up to 8 amp. It was behaving like it is working (voltage went up somewhere around 4 or 5 V – I do not remember) except the spot was like it is at 1% of power.

But that’s ok, I have got “80W” Neje with 2 LEDs, beams combined with a mirror.

Of course, optical power is not 80W. But I am not sure how to measure it (boil some water with it? how?)

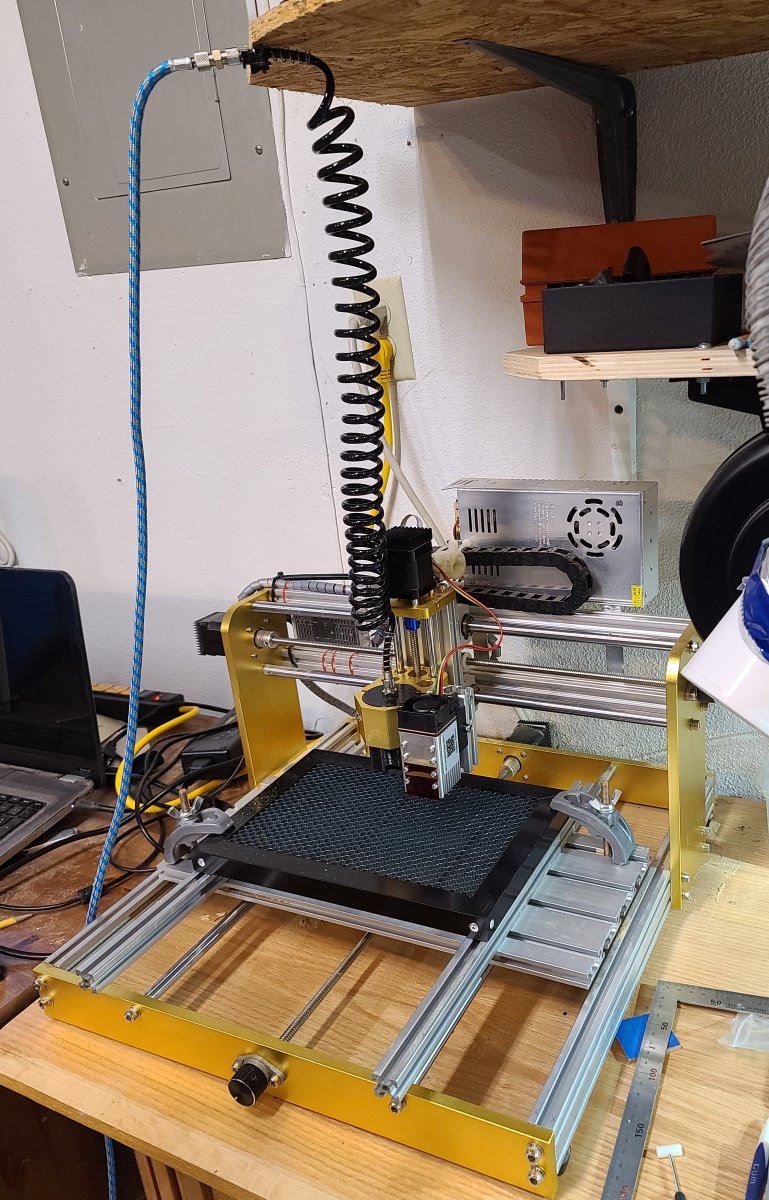

Anyways, Neje could be milled down to fit 52mm spindle mount. But I prefer to mount it outside with a piece of 2040 (can you spot it behind the laser?).

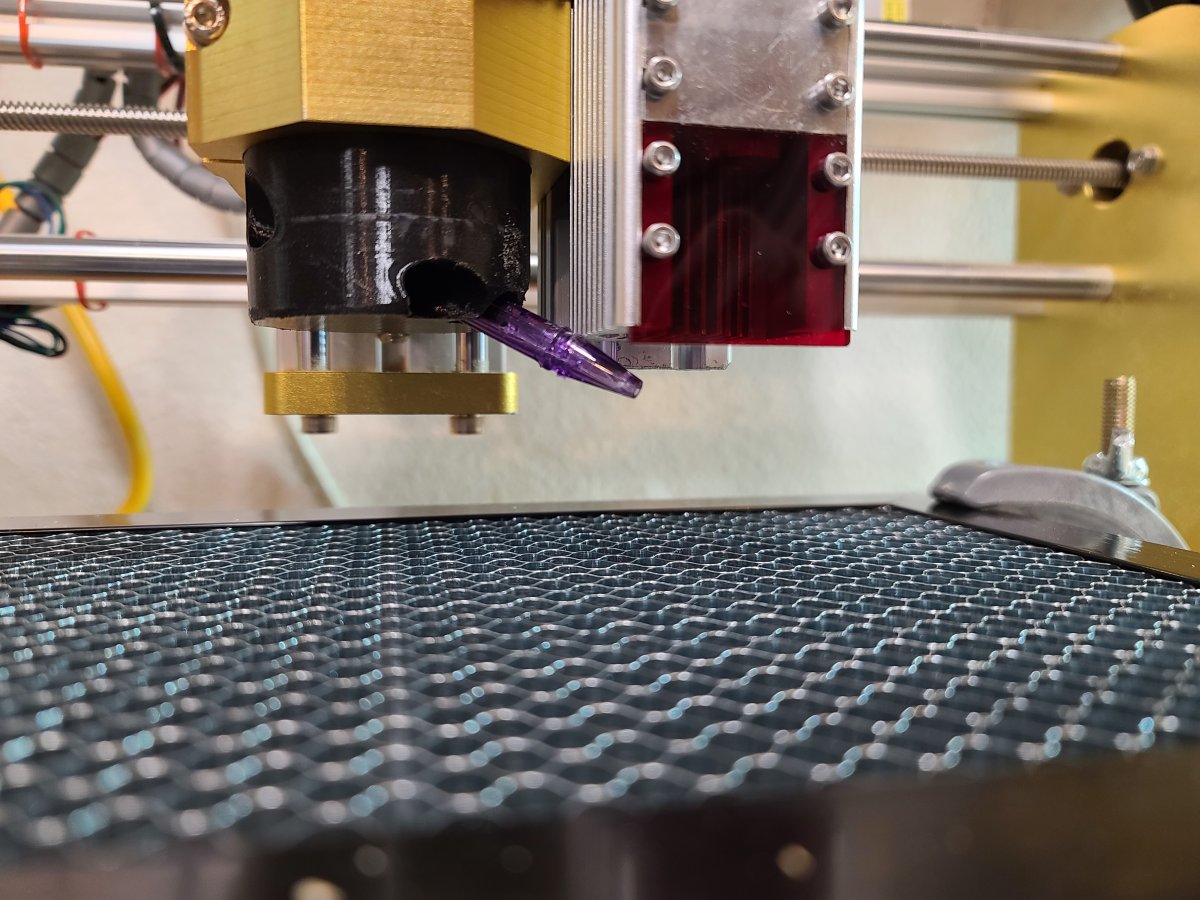

And what is that black thing in the spindle mount? Oh, that’s my air assist

But why there are so many holes? Well, I had an idea to add 2 more lasers that produce lines – for aligning the milling part without turning on the main laser. My drill press does that:

However, I have not installed them yet and not sure whether I am going to do it. Air assist works great though (yes I am using a part of a pen to channel the airflow).

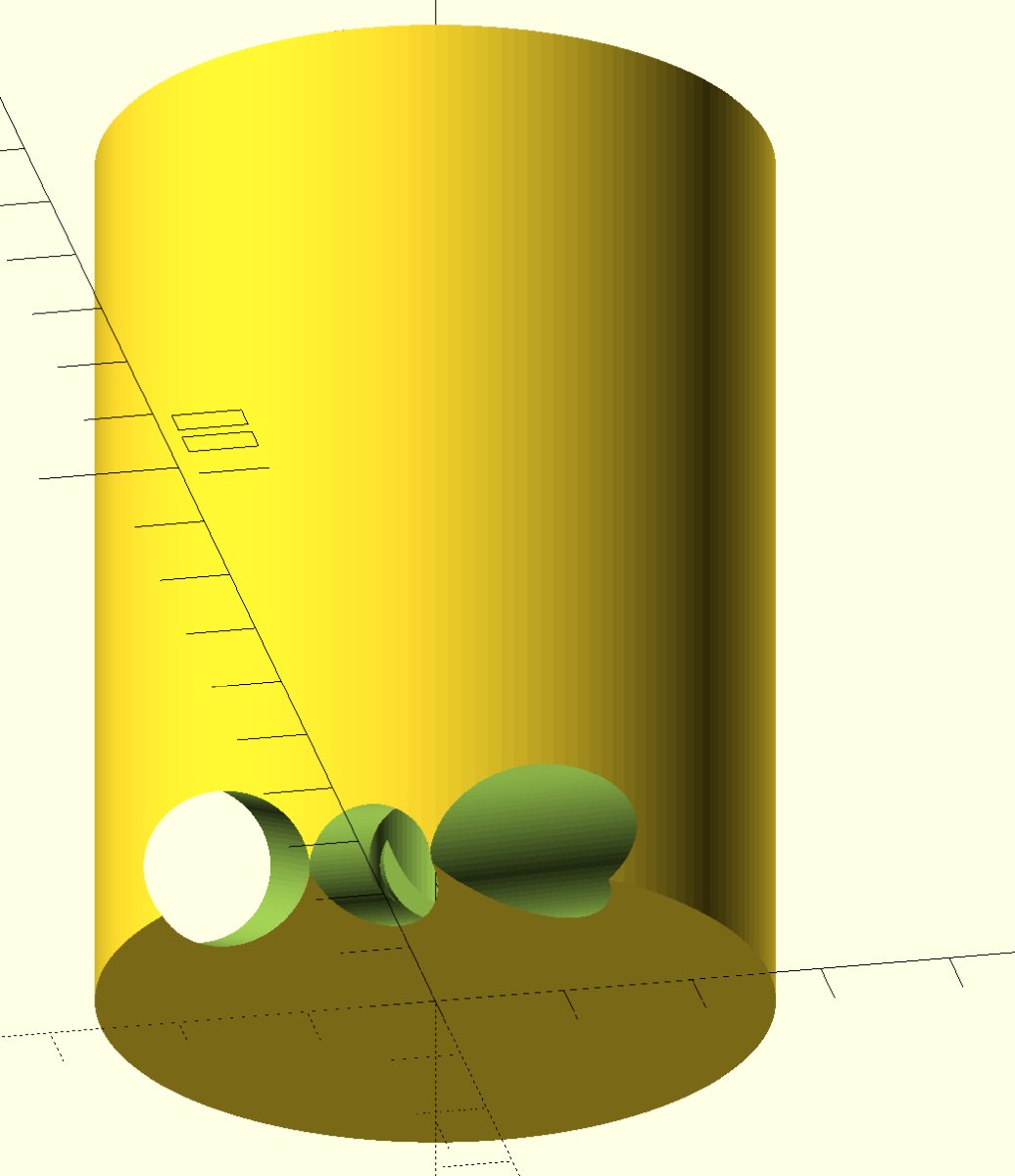

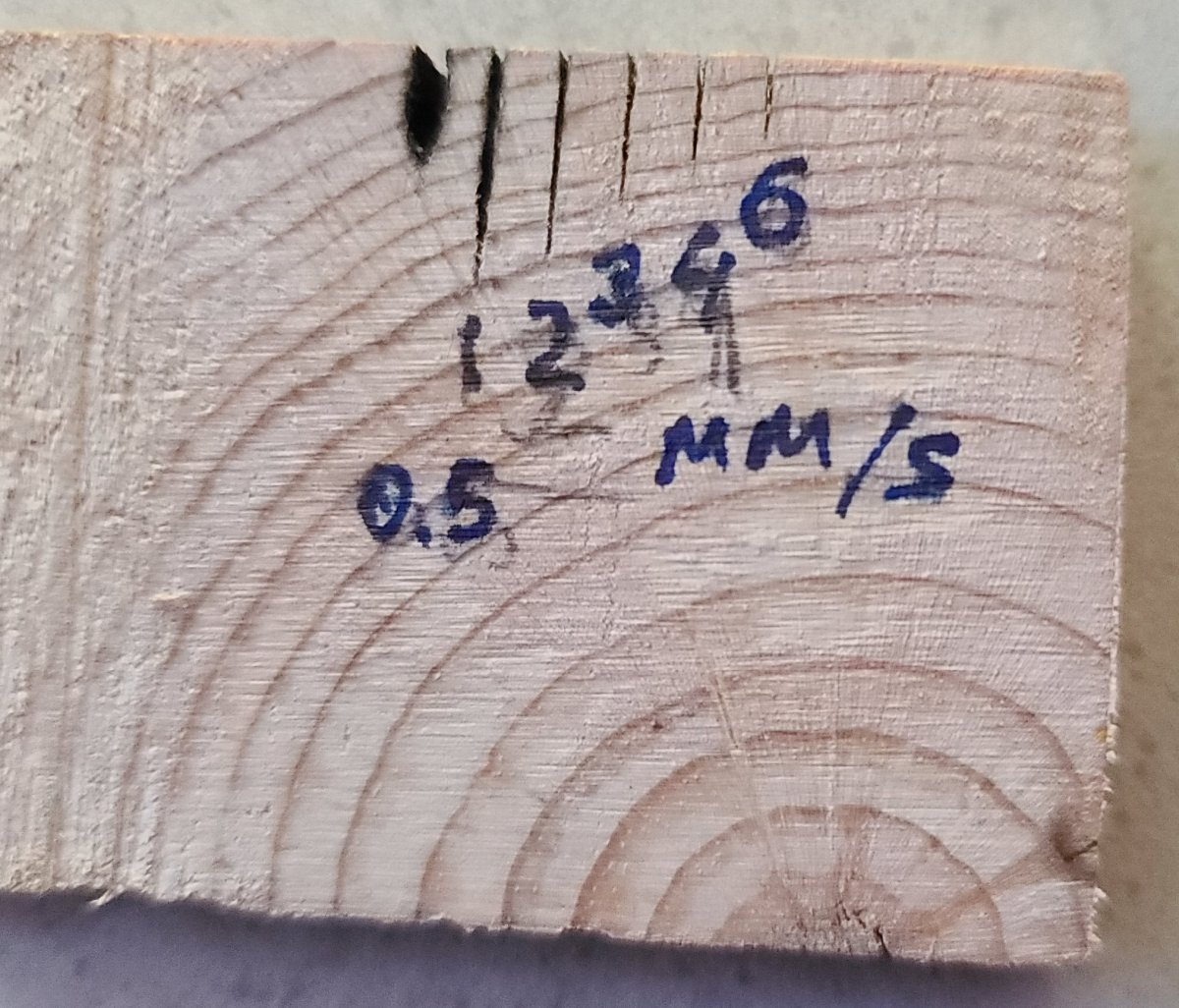

So… The laser pretends to be 80W, but how deep can it cut? Well, here is the answer:

As you can see, the slower you go – the deeper you cut. Until you go below 1mm/s and put your wood on fire. The deepest cut I achieved is 11mm at 1mm/s. 2mm/s produces 9mm cut, 3mm/s – 7mm cut, 4mm/s – 5mm cut. This is single pass. I would guess, with multiple passes it might be possible to cut deeper.

But this is wood. Plywood is harder to cut due to glue layers.

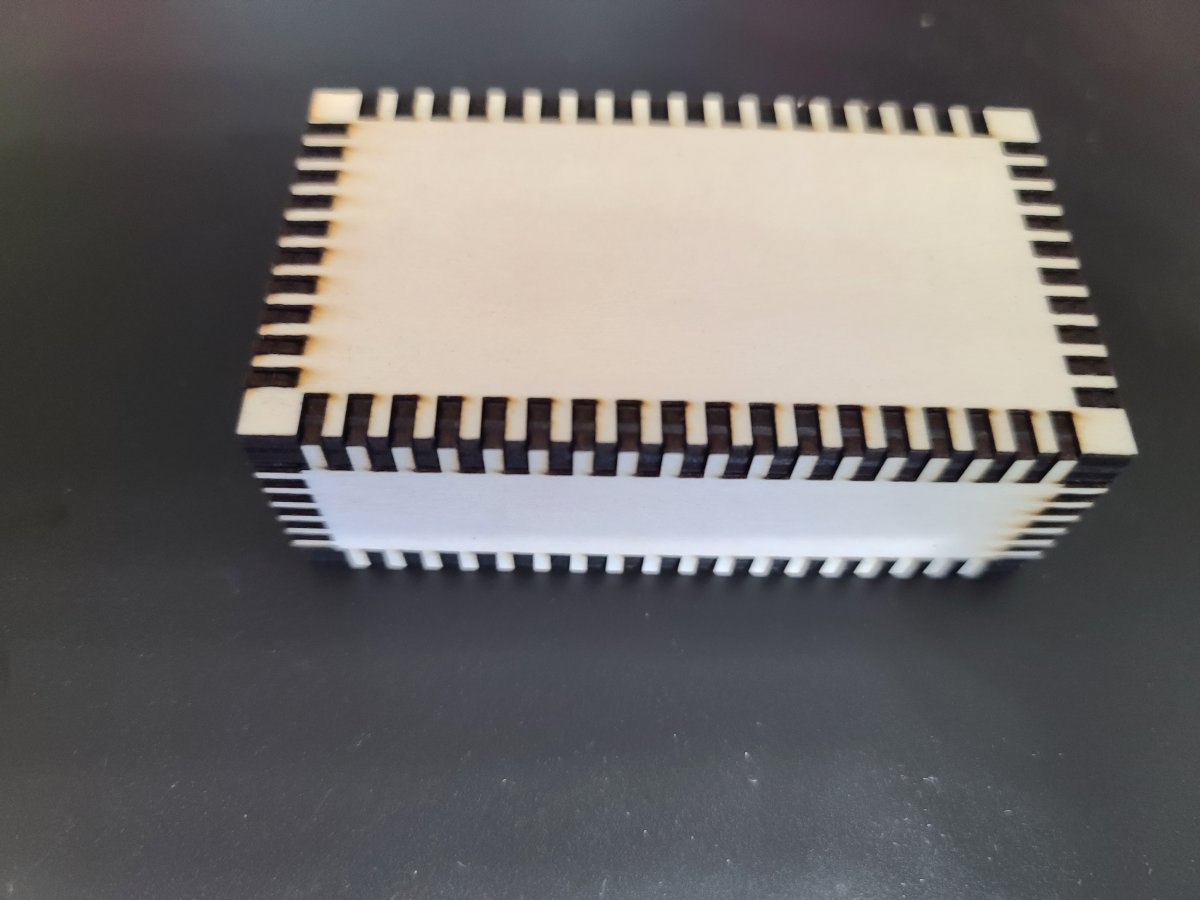

I can easily cut 5mm plywood at 2mm/s. Perhaps, I could of go a little faster.

It is really nice to go from 3mm to thicker plywood. It just feels so much better in your hands. One thing to watch for: plywood thickness. Softwood 1/4 inch plywood is 1/4 inch thick. Hardwood 1/4 inch plywood is mostly 5mm thick. 5mm is still pretty good, but…

Why? Why hardware stores are lying to me like that? Why don’t they just be honest and say “5mm plywood”?

But wait a minute! Aren’t I have 1mx1m laser cutter? What happened to it? Why do I need to use this small CNC for laser cutting?

Yes I still have the 1mx1m laser cutter. BTW, I use 40W Neje there and it works great.

However, my 1mx1m CNC is not very sturdy, so I cannot achieve a good accuracy and repeatability with it. I tried to tune it up by gluing parts together, and it helped somewhat, but I still want better accuracy.

I am still using 1mx1m for large format low accuracy projects. 1mm error is usually not noticeable on half-a-meter cuts or engravings.

The bottom line:

* Neje rocks!

* Modern LED lasers are good enough for most practical purposes (80W rocks!)

* Don’t even think about laser cutting or engraving without a good air assist!